Logistic issues and challenges don’t add up with multiple warehouses. They multiply. Retail businesses, like high street shops and e-shops, enjoy growth. Doing retail business in scale usually means better competitive prices, higher availability, and better margins. Growing from a single warehouse to a multiple warehouse organisation is so tricky that it can eventually kill the entire organisation, especially when the inventory management is sub-par.

Multiple warehouses require processes, automation, and dashboard-guided management. The traditional small retail leadership based on intuition and hard work no longer proves useful with multiple warehouses.

With every new warehouse, SKUs almost double

Once a product item sits in a different location, it becomes a new item in terms of inventory management. The number one factor that influences everything else, is demand. Demand differs for each warehouse; thus, any calculations, any prediction, or any inventory strategy setting is always relevant to each warehouse alone. But at the same time, no warehouse is an island, and everything is connected into one business entity, i.e. your company.

Making decisions about your inventory has to be done in the context of local demand and at the same time in the context of the whole supply chain. This is mind-blowing at first but becomes a natural process once you get used to it.

The takeaway from this section is that you need to create purchase orders for each warehouse alone, and you shouldn’t make your life easier just by ordering the same stuff in the same amounts to multiple different locations.

Product availability in a multi-warehouse company

We wrote about product segmentation quite a bit already on our page. We recommend you go through our older texts on this topic to get a better idea. For now, we will fast forward this text to say that product segmentation leads to dividing the items in your portfolio into three categories:

- Winners – The cash cows of your portfolio creating a majority of your sales

- Chasers – The majority of your stock, creating your product range

- Losers – Your inventory trash creates nothing but loss

You may choose to look at product segmentation from the perspective of the whole company, and you may choose to do so from the perspective of each warehouse. What might be a winner in one location could be a loser in another. You can make these views quite easily in our app.

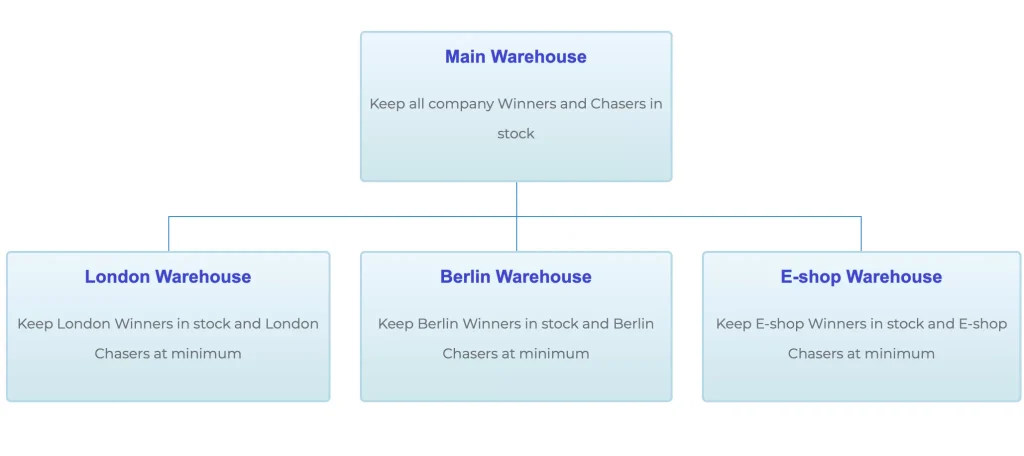

In a small environment, you would keep Winners available as much as possible, Chasers somewhat available, and Losers unavailable. But when it comes to availability in a multi-warehouse environment, the biggest retail companies in the world would choose a scenario similar to this:

Inventory management is all about keeping warehouses small and goods available at the same time. That’s the goal. Instead of making your multi-warehouse scenario a pain for your organisation, you want to use the advantage of all the locations. This all starts with product segmentation.

If you want to get serious about inventory management, you need to do demand planning. And demand planning is hard, but it is the only effective way to make a difference in inventory size and product availability.

Demand planning for multiple warehouses

The logic is simple. If you want to optimise, you need to know what’s coming at you. Suppliers supply their goods sometimes within days, often within weeks. And you can’t solve inventory with a last-minute fas fix attitude. You need to plan ahead.

With our software, you will be able to forecast based on everyday calculations. It will all look very easy to you, but what you will not see is over 100 algorithms doing billions of calculations overnight just to get that forecasting graph delivered to your screen every morning.

With multiple warehouses, the same one-by-one logic applies to demand planning as well. You need to forecast demand for the company as a whole and then for each warehouse alone. Again, our app allows you to do this quite easily, just by choosing the correct filter.

Replenishment for multiple warehouses

Once you know your product segments and your forecast, you are ready for the final stage of multi-warehouse inventory management – purchase orders. This is where the complexity of everything really steps in.

In a multilevel warehouse scenario, just like the one described above, you become your supplier, where the central warehouse is the supplier for the smaller satellite warehouses. Although you are the same company, you need to start thinking of yourself as an internal customer of yourself. As mentally painful as this can be, it is the best and fastest way how you set yourself to get inventory right across your warehouse chain.

In practice, you know your forecast for each warehouse, so it should not be an issue to create a purchase order list for each warehouse every day. This might take hours by hand or one click in an app.

Either or, you are left with several possibilities. You order goods from your suppliers to your main warehouse and distribute the goods to your satellite warehouses from there. Or you can do a mix. You can order goods to the master warehouse and order some goods (winners, for example) to your satellite warehouses directly at the same time.

To understand which scenario works best, you need to create a distribution plan. There are books which we could write about distribution plans. It really is a video topic. Today we are just going to leave you with the general idea that every distribution plan needs to source those local lists. Without exact numbers for each day, every plan is just pure theory.

This leads us to the last point of inventory management. The point applies to a single warehouse as well as multiple warehouse businesses. YOU NEED TO DO IT EVERY DAY. Inventory management is something that cannot be just dealt with, and then you can do something else tomorrow. Seasons, demand, pricing, price promotion, weather, coronavirus, cannibalisation, or strictly external factors. They all lead to a change in demand. Once demand changes (and it changes every day), the whole inventory management machine changes, and you need to adapt immediately.

Please enjoy the range of articles we have provided to help your ecommerce business succeed.